The buyer entrusts the seller to manufacture GHQ250-700 angle steel flame bending machines. After mutual consultation, the agreement is signed as follows:

1.Equipment name: GHQ250-700 angle steel bending machine.

2.Equipment quantity: One unit.

3.Delivery time: Within 20 working days after the contract takes effect.

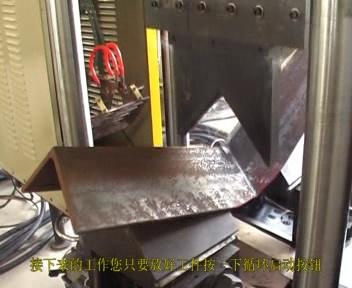

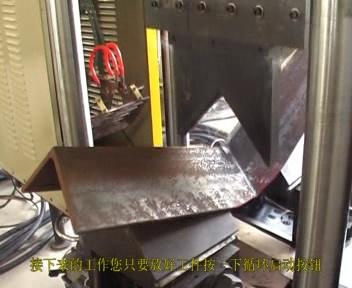

4.Equipment use: The angle steel bending machine is mainly used for angle steel bending and sheet metal bending.

5. Application industry: Angle bending machine is mainly used for angle bending and plate bending. It is suitable for power transmission line tower, communication tower, power fittings, steel structure, storage shelf and other industries.

6.Machine Purpose:

1)It adopts PLC controller, touch screen to input information and state feedback, easy to operate.

2)Intelligent super audio induction heating is adopted to improve production efficiency, reduce production cost and ensure the working environment of the company.

3)Angle steel bending machine, to achieve a machine for multiple purposes, do not need to be equipped with other tooling mold.

4)Numerical control ensures the forming angle of workpiece, ensures the quality of products and improves the production efficiency.

5)Angle steel fire bending machine has independent hydraulic system and electrical control system, which is simple and convenient to operate, safe and reliable in performance and high in production efficiency.

6)Angle steel processed by angle steel bending machine is less than L100 × L100 × 10 bending degree less than 5 ° Cold pressing can be used.

7)Processing speed: cold pressing for 10s / time, heating processing for 120s / time (determined according to actual processing materials and materials) when the heating temperature is 800 (i.e. red), the workpiece is processed (determined according to the actual material and bending angle).

8)When the workpiece is heated, design the parameters, press the cycle start or step down the foot switch to complete the heating forward, heating, heating exit, pressing the workpiece, rising the head and taking out the workpiece automatically.

9)When heating and cold pressing, the parameters are designed and the cold pressing is carried out directly. The pressing head does not need to return to the origin. The pressing die raises the clearance of 100 mm and takes out the workpiece. The work efficiency is high.

7.Main technical specifications:

1 | Oil Cylinder Pressure (kN) | 1600 |

2 | Dual Bending Range (mm) | L80*7~L250*32 |

3 | Dual Bending Angle | 30° |

4 | Processing range of positive single bending (mm) | L80*7~L200*18 |

5 | Positive single bending angle | 20° |

6 | Thickness of curved plate (mm) | 2~16 |

7 | Processing width of curved plate (mm) | 700 |

8 | Bending angle of curved plate | 90° |

9 | Oil cylinder stroke (mm) | 800 |

10 | Machine power (kW) | 15 |

11 | Heating power (kW) | 60*2 |

12 | CNC Axis Numbers | 3 |

13 | Cooling water tank (m³) | 6 |

14 | Cooling tower flow rate (m³/h) | 50 |

15 | Oil tank volume L | 630 |

16 | Machine weight (tons) | About 8 |

17 | Machine Overall Dimensions (mm) | About 3500*4500*4100 |

9.Free Accessories list:

NO | Name | Mode | Unit | Quantity | Remark |

1 | Spindle | GHQ250~700 | Set | 1 | equipment |

2 | Control cabinet | GHQ250~700 | Set | 1 | equipment |

3 | Hydraulic system | GHQ250~700 | Set | 1 | equipment |

4 | heater | JR-60 | Set | 2 | equipment |

5 | Heating Spindle | JR-60 | Set | 2 | equipment |

6 | Hyperbolic mold | GHQ250~700 | Set | 1 | equipment |

7 | Single mold | GHQ250~700 | Set | 1 | equipment |

8 | Curved plate mould | GHQ250~700 | Set | 1 | equipment |

9 | Lower die base | GHQ250~700 | Set | 2 | equipment |

10 | Upper mold support | GHQ250~700 | Set | 1 | equipment |

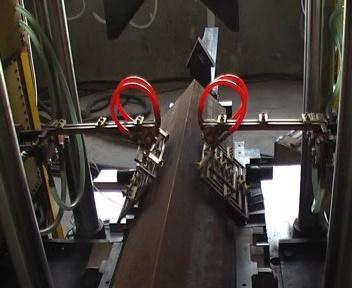

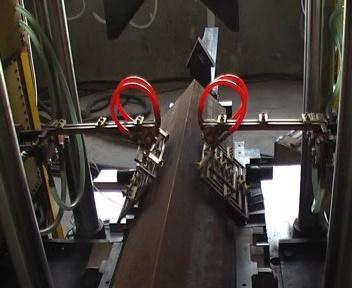

11 | Induction loop | GHQ250~700 | Set | 2 | equipment |

12 | Double end open end wrench | 24*27 |

| 1 | tool |

13 | Adjustable wrench | 250mm | pic | 1 | tool |

14 | inner hexagon spanner | 4#-14# | Set | 1 | tool |

15 | inner hexagon spanner | 12mm | pic | 1 | tool |

16 | slotted screwdriver | 6*150 | pic | 1 | tool |

17 | Cross screwdriver | PH2*150 | pic | 1 | tool |

18 | High pressure machine oil pot | 250ml | pic | 1 | tool |

19 | Equipment manual | XinGao | Set | 2 | document |

20 | Combined washer | GHQ250~700 | Set | 1 | parts |

21 | Equipment safety operation procedures | XinGao | Set | 2 | document |

22 | Equipment certificate | XinGao | Set | 2 | document |

23 | Delivery receipt | XinGao | Set | 1 | document |

24 | Equipment acceptance form | XinGao | Set | 1 | document |