1.Machine Purpose:

ADM2532 CNC angle steel high speed drilling production line is mainly used for drilling and stamping of large size and high strength angle steel in transmission line tower. All the holes on the angle steel can be drilled in the production line, with high quality and position accuracy, high production efficiency and automation

2.Machine Features:

1)High degree of automation. The production line is equipped with automatic feeding device (transverse feeding channel)

2)All the holes and steel marks on the angle steel can be processed by the production line at one time without manual assistance, which can greatly reduce the labor intensity of workers

3)The position precision of hole making is high. The feeding device of the production line is driven by servo motor, driven by gear and rack, and equipped with detection rack and gear, detection encoder for position accuracy feedback, forming a full closed-loop control; The movement of the drilling power head in the direction of the two wings of the angle steel is driven by the servo motor and driven by the ball screw, so as to ensure the high accuracy of the position of the hole on the angle steel workpiece

4)Drilling efficiency and drilling quality are high. The drilling unit is equipped with six groups of NC drilling power

5)There are three groups on each wing of the angle steel. For the same hole diameter with the same distance between the two wings of angle steel, the corresponding drilling power head on both sides can drill at the same time. The CNC drilling power head adopts the special spindle frequency conversion motor which can be forced to pass. The motor drives the drilling spindle through the synchronous belt. The drilling spindle adopts Taiwan BT40 precision spindle (internal cooling), and the drill bit adopts cemented carbide drill. The cutting speed of the drill bit can reach 200m / min (25-30m / min for high speed steel twist drill), and the feed speed is fast. The servo motor drives the NC drilling power head to feed, and the fast forward, work forward and fast backward of the drill are controlled by the NC system and automatically completed. The back position of the bit can be set in the upper computer, which reduces the empty stroke and further improves the production efficiency. The tolerance of hole diameter is less than 0.1 mm and the finish RA is less than 6.3 μ m. The processing quality of the hole is high

6)The drilling spindle is equipped with disc spring automatic broach mechanism. The hydraulic cylinder releases the tool and replaces the tool

7)The handle is very convenient. The front end of the spindle adopts labyrinth protection, waterproof design and is equipped with air curtain device, which can ensure that the cutting fluid does not enter the spindle

8)MQL (minimum quantities of lubricant) cooling system is the most advanced cooling system in the world. MQL system can mix compressed air with a very small amount of lubricant (cutting oil) and spray it to the processing area for effective cooling and lubrication. The cutting oil consumption is very small, about 550ml / h. The use cost of the coolant is low, and the cooling and lubrication effect is remarkable, which can ensure the tool life and further improve the quality of hole processing. The cutting oil is a vegetable oil-based product, which has no pungent smell, non-toxic and side effects, and is fully vaporized in the process of processing, with almost no residue. Therefore, the MQL system is environmentally safe, and there is no oil leakage, effusion, ground pollution, abnormal smell around the machine tool, which is conducive to 5S site management

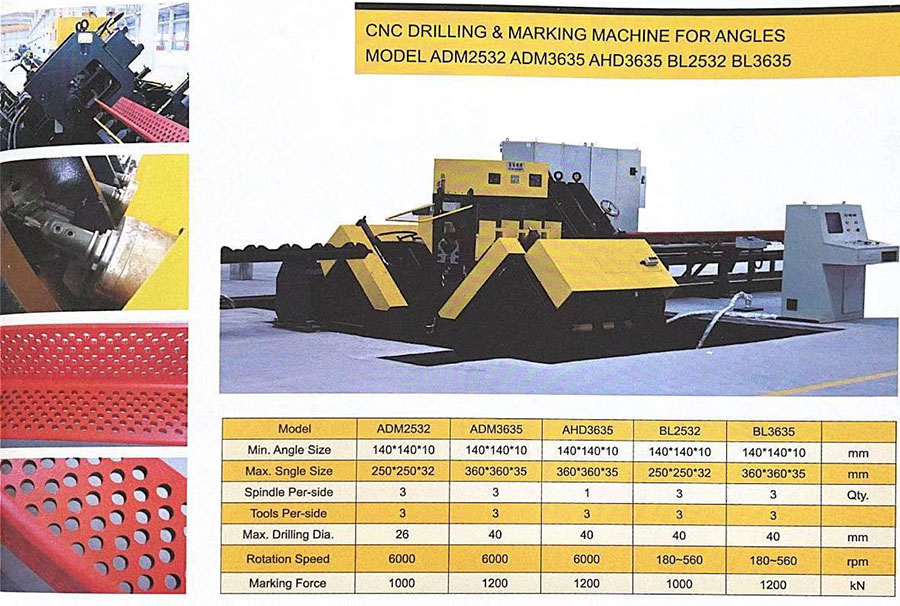

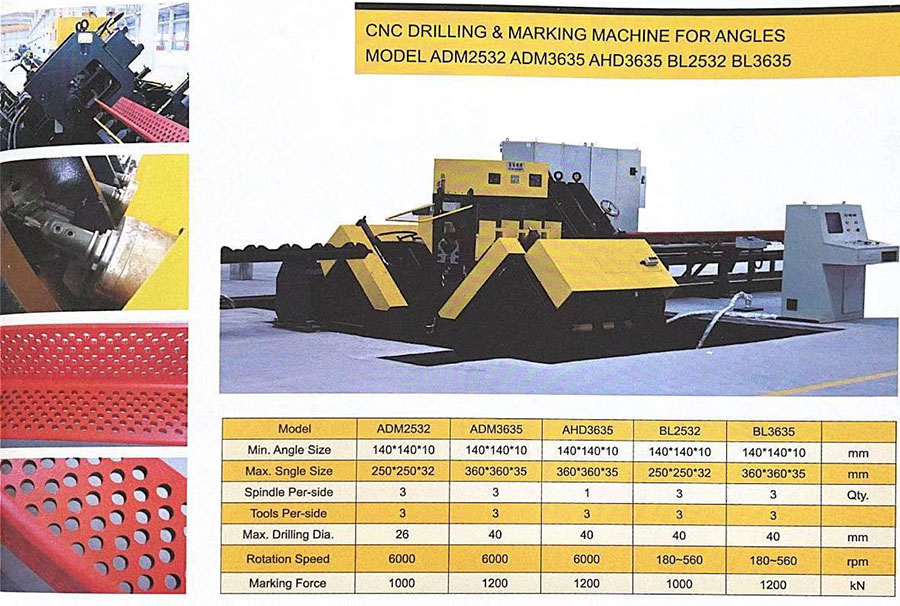

3.Main Technical Specifications:

1)Angle size(mm): 140×140×10 ~ 360×360×35

2)Range of stadia(mm): 50 ~ 220(stepless)

3)The quantity of drilling cow per side: arbitrariness

4)Quantity of drilling spindle per side: 3

5)Range of drilling diameter(hard metal)(mm): φ17.5 ~ φ26mm

6)Quantity of CNC axis: 9

7)Maximum speed of drilling spindle: 6000r/min

8)Max length of workpiece (m): 12

9)Angle feeding speed (m/min): 40

10)Quantity of character group: 1 group

11)Number of prefix in each group: 18

12)Spindle taper: BT40

13)Marking Force(KN): 1030

14)The finished angle conveyor is rotated to one side by pneumatic power, the max length of finished angle is12m.

15)There are four sets of transverse conveyor, infeeding automatically and intermittently.

16)Type of programming: keyboard input, USB interface input, floppy disc input.

17)Working environment:

Working temperature: 0℃~ 40℃

Power: Three phase four wire systems

AC Voltage: 380V

Fluctuation of voltage: ±10%

Frequency: 50 Hz ±1

4.Work Environment:

1).Power supply: 3 phase 4 lines 380±10%V 50±1HZ

2).Compressed air pressure: ≥0.5MPa

3).Temperature: 0-40°C

4).Humidity: ≤75%