1. Machine Purpose:

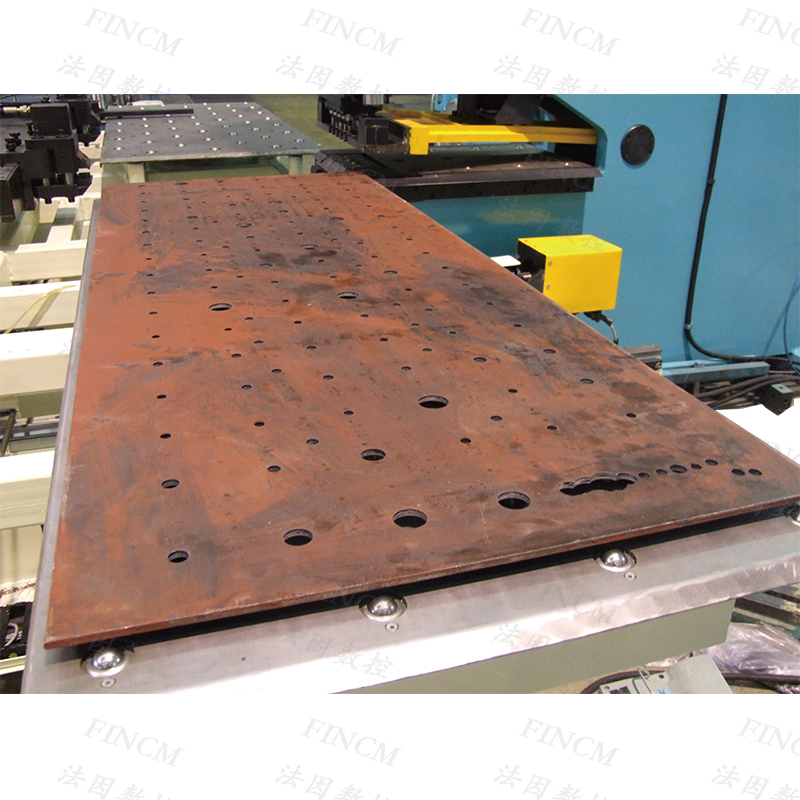

The CNC punching machine for automobile trabeculae is mainly used for punching small and medium sized plates in the Truck industry. The workpiece can be punched after one-time clamping to ensure the position accuracy of the hole. It has high work efficiency and degree of automation, and is especially suitable for mass production. This machine tool can process a plate of 800mm×3500mm (Width x Length) in one clamping, and the maximum plate size of 800mm×7000mm (Width x Length) can be processed through the second positioning and transfer of the auxiliary clamp.

2. MainTechnical specification

Punching Force | KN | 1200 |

Maximum plate size (Width x Length) | mm | 800×3500 (one time’s positioning) 800×7000(Secondary positioning) |

Plate thickness range | mm | 4~12 |

Punching Station | Punching position number |

| 13 |

Maximum punch diameter | mm | φ65 |

Punch size (mm) | φ9、φ11、φ13、φ15、φ17、φ21、φ22、φ30、φ34、φ36、φ45、φ50、φ65(A set of die with plate thickness of 8mm or 6mm) |

Number of punches | Per minute | 〉42 |

Warpage | mm | <25 |

Minimum distance from hole centerline to the boundary edge | mm | See punching tool layout picture |

Number of clamps |

| 3 |

System pressure | high pressure | MPa | 24 |

low pressure | MPa | 6 |

Air pressure | MPa | 0.5 |

Motor power of hydraulic pump | kW | 22 |

X-axis servo motor power | kW | 5 |

Y-axis servo motor power | kW | 5 |

Total capacity | kVA | 55 |

Accuracy of hole position on plate after punching:

Work Condition | Accuracy of X, Y axis |

When the hole spacing is less than or equal to 400mm | ±0.2mm |

When the hole spacing is greater than 400mm and less than 2000mm | ±0.30mm |

When the hole spacing is more than 2000mm and less than 3500mm | ±0.50mm |

When the hole spacing is more than 3500mm and less than 7000mm | ±1mm (Secondary positioning) |

3. Main outsourcing components list

NO | Name | Brand | Country |

1 | CNC | Siemens 808D | Germany |

2 | Servo motor and servo driver | Siemens / Panasonic | Germany/ Japan |

3 | Linear motion guide rail | HIWIN/PMI | Taiwan, Chian |

4 | Ball screw | I+F/NEEF | Germany |

5 | Cylinder | SMC/FESTO | Japan /Germany |

6 | Solid state relay | Weidmuller | Germany |

7 | Towline | Igus/CPS | Germany/ South Korea |

8 | Double vane pump | Denison/Albert | USA |

9 | Hydraulic Valve | ATOS | Italy |

10 | Oil cooler | Tongfei/Laber | China |

11 | Oil lubrication device | Herg | Japan |

12 | Low voltage electrical components | Schneider | France |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components in case of any special matter.

4. Work Environment:

1).Power supply: 3 phase 4 lines 380±10%V 50±1HZ

2).Compressed air pressure: ≥0.5MPa

3).Temperature: 0

4).Humidity: ≤75%