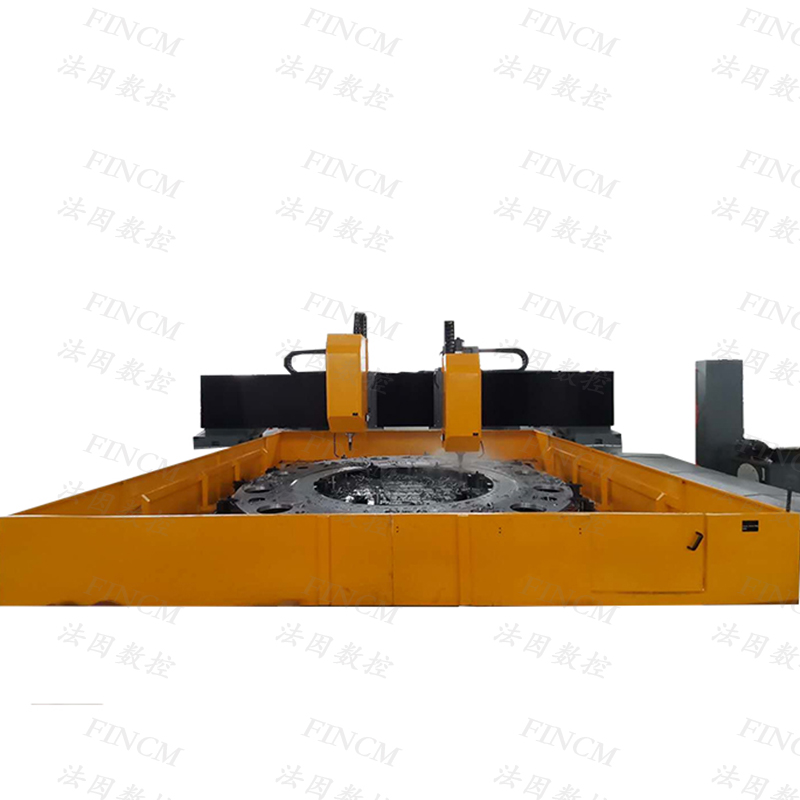

1.Product Description:

This machine is a gantry mobile CNC drilling machine, which is mainly used for drilling diameter φ Drilling, milling, grooving, chamfering and light milling of tubesheet and flange parts below 60.

1) Technical specification of PLM4040/2

Maximum machining workpiece size | Length x width | 4000×4000 mm |

Maximum processed plate thickness | 250 mm,Scalable to 380mm |

Workbench | Workbench Size | 4500×4000 mm |

T-groove width | 28 mm |

load-bearing | 3t/㎡ |

Drilling power head | Maximum borehole diameter | φ60 mm |

Maximum aperture ratio | ≤10(Crown drill) |

Spindle speed | 30-3000 r/min |

Spindle taper | BT50 |

Spindle motor power | 2×22kW |

Maximum spindle torquen≤750r/min | 280Nm |

Distance from lower end face of main shaft to worktable | 280—780 mm (Adjust according to workpiece thickness) |

Gantry longitudinal movement (x-axis) | Maximum stroke | 4000 mm |

X-axis moving speed | 0—8m/min |

X-axis servo motor power | 2×2.7kW |

Lateral movement of power head (Y-axis) | Maximum distance between two power heads | 4000mm |

Y-axis moving speed | 0—8m/min |

Y-axis servo motor power | 2×2.7kW |

Feed motion of power head (Z axis) | Z-axis travel | 500 mm |

Z-axis feed speed | 0—4m/min |

Z-axis servo motor power | 2×3.3kW |

positioning accuracy | X-axis、Y-axis | 0.08/ whole course |

Repeat positioning accuracy | X-axis、Y-axis | 0.04/ whole course |

Hydraulic system | Hydraulic pump pressure / flow | 15MPa /25L/min |

Hydraulic pump motor power | 3.0 kW |

Pneumatic system | Air supply pressure | 0.5 MPa |

Chip removal and cooling | Chip conveyor type | Flat chain |

Number of chip conveyor | 2 |

Chip removal speed | 1m/min |

Chip conveyor motor power | 2×0.75kW |

Cooling mode | Internal cooling + external cooling |

Maximum pressure | 2MPa |

Maximum flow | 2×50L/min |

Electrical system | CNC | Siemens 828D |

CNC Number | 6 |

Total motor power | About75kW |

Overall dimensions of machine tool | Length× Wide × High | About 9m×9m×3m |

Total weight of machine tool |

| About 40t |

Work Environment:

2) List of accessories and spare parts of PLM4040/2

NO. | Name | Code | QTY |

1 | Photoelectric edge finder |

| 1 |

2 | inner hexagon spanner |

| 1 Set |

3 | Knife handle and pull nail | Φ40-BT50 | 2 |

4 | Knife handle and pull nail | Φ20-BT50 | 1 |

5 | Paint (for touch up) | -- | 2 Kegs |

3) List of the Key Outsourced Components of PLM4040/2

NO. | Name | Brand | Country |

1 | linear guide rail | HIWIN/PMI | Taiwan, China |

2 | CNC | Siemens | Germany |

3 | Servo motor and driver | Siemens | Germany |

4 | Precision spindle | KENTURN /SPINTECH | Taiwan, China |

5 | Hydraulic valve | YUKEN / Justmark | Japan |

6 | Oil pump | Justmark | Taiwan, China |

7 | Automatic lubrication system | BIJUR / HERG | USA or Japan |

8 | Buttons, indicator lights and other main electrical components | SCHBEIDER/ABB | France /Germany |