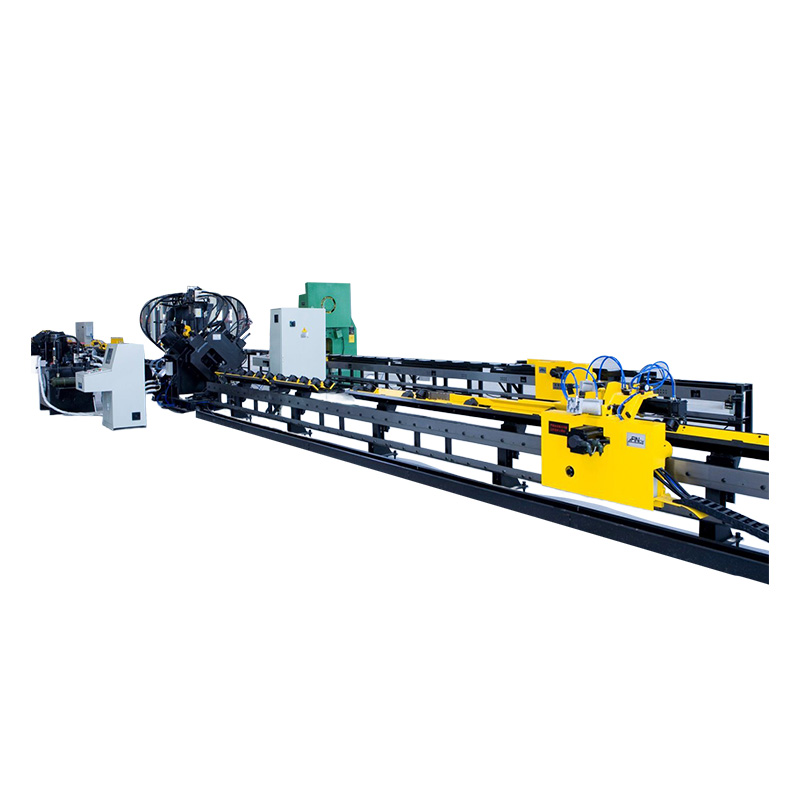

1.Machine Purpose:

It is mainly used for manufacturing angle steel components in iron tower factory, typing, punching and completing fixed length cutting on angle steel

2.Machine Features:

a)The typing unit adopts a closed body, which is very strong. With four transposable prefix boxes, each prefix box can hold 18 characters

b)Each punching unit is equipped with three mold bases, which can punch holes of three different diameters on each side of the angle steel. The servo motor drives to change the gauge, and the gauge can be adjusted steplessly

c)The angle steel is clamped by a pneumatic clamp, which can move and locate quickly. X-axis feeding adopts servo motor drive, rotary encoder feedback, full closed-loop control, high precision; trolley vertical lifting, when returning, does not affect feeding, improves processing efficiency

d)The transverse material path is composed of four chains with shifting block and frame body, and the chain is driven by motor through reducer

e)The discharge channel is composed of channel body and cylinder. The finished angle steel is thrown out of the production line by the rotation of the main part

f)This machine has three CNC axes: the movement and positioning of the feeding car, the up and down movement and positioning of the punching unit mold base

g)It is easy to program by computer. It can display the workpiece figure and the coordinate size of the hole position, so it is easy to check. It is very convenient to store and call the program, to display the graph, to diagnose the fault and to communicate with the computer

3.Main Technical Specifications:

Angle size | 63×63×4-200×200×20 (Q345) |

Nominal Marking force | 1030 |

Nominal punching force | 1100 |

Nominal Shearing force | 1800 |

Maximum punch diameter (mm) | φ26 |

Maximum blank length (m) | 14 |

Maximum length of finished product (m) | 12 |

Number of print header groups | 4 |

Number of prefixes per group | 18 |

Prefix size (mm) | 14x10x19 |

Feeding speed of angle steel (M / min) | 60 |

Cooling mode | water-cooling |

Cut off mode | Double edged cutting |

Total power of equipment (kw) | 43 |

Machine dimension (m) | 32×7×3 |

Net weight (T) | About 18 |

4.Work Environment:

1).Power supply: 3 phase 4 lines 380±10%V 50±1HZ

2).Compressed air pressure: ≥0.5MPa

3).Temperature: 0-40°C

4).Humidity: ≤75%