1.Machine Purpose:

The machine is mainly used for drilling and cuttingplate workpiecesin steel structures such as buildings, bridges, iron towers, plate logistics, boats and ships manufacture,etc..

This machine tool can be used for mass continuous production, also can be used for multi variety small batch production, and can store a large number of workpiece program, produced workpiece, next time out can also process the same kind of work piece.

2.Machine main structure and configuration:

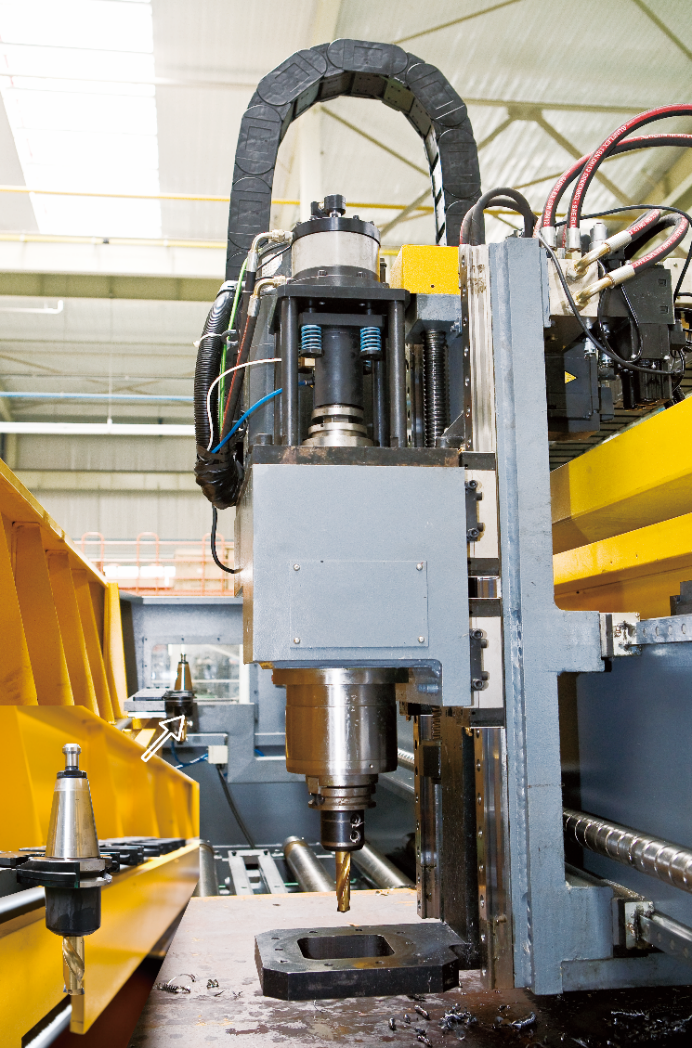

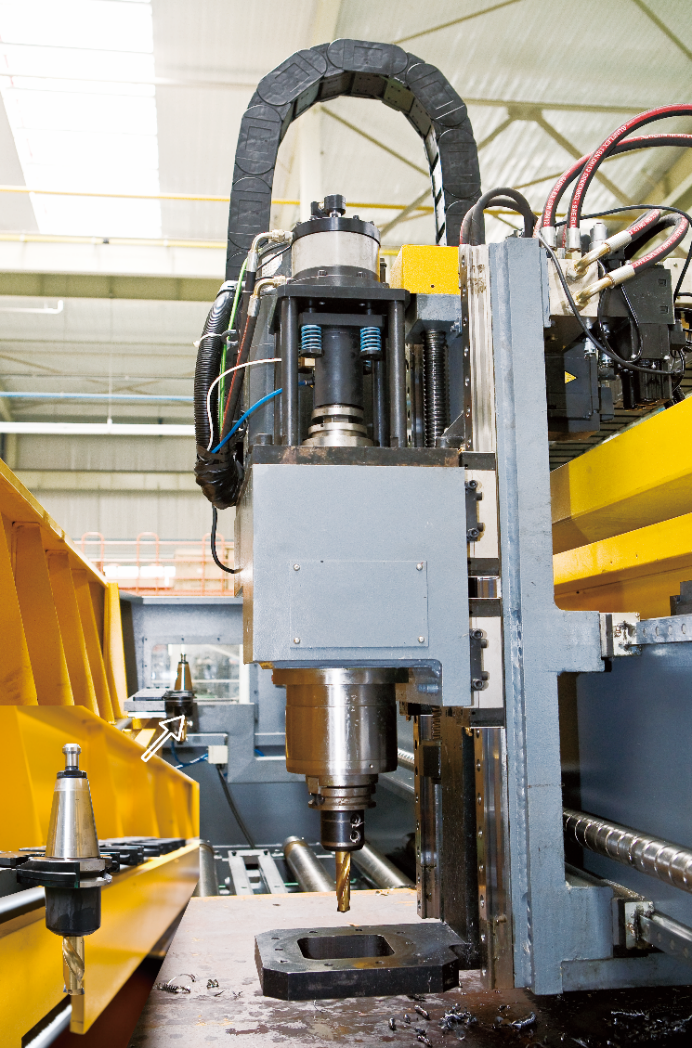

The machine is mainly composed of machine body, CNC infeeding and output device , drilling head, marking system, cutting system, cooling system, lubricating system, hydraulic system, Electric control system, centralized lubrication system, cooling chip removal system etc.

There are 6 CNC axes. This machine adopts imported driving parts(Linear guides, ball screw, gear and rack etc..)to ensure the reliability and positioning precision. Hydraulic It complete the feeding action by pushing and pulling clamp.

It adopt oil mist cooling method for the cutting tools, has the advantages of less pollution, clean environment, low cost, etc.

It adopt precision spindle with high rotation accuracy and good rigidity. Equipped with BT50 taper hole(inner cooling), it is convenient to change the tool. It can be used for clamping twist drills and hard alloy drills, which has a wide range of applications. The main shaft is driven by a main shaft frequency conversion motor, which has a wide range of applications. The speed can be continuously variable in a wide range to meet the needs of multiple speeds.

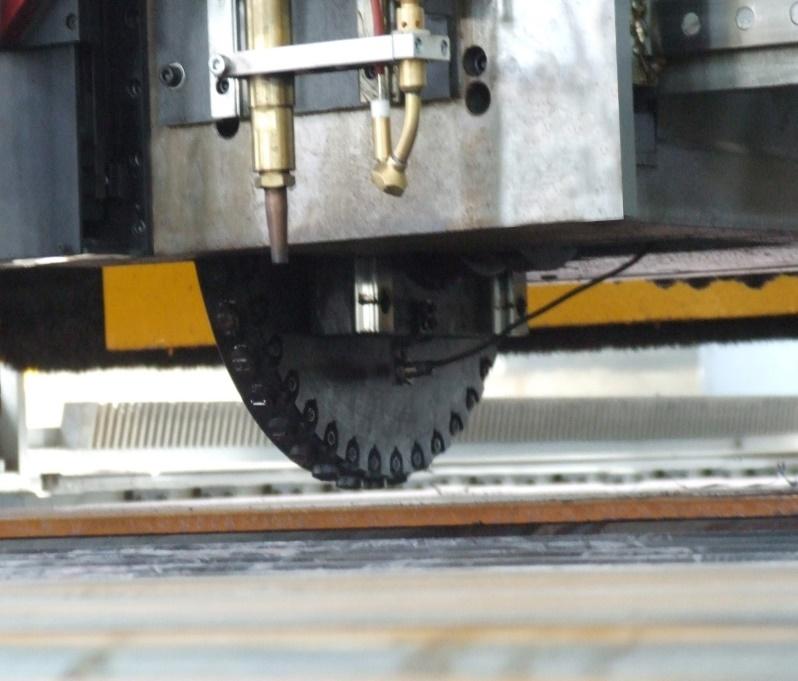

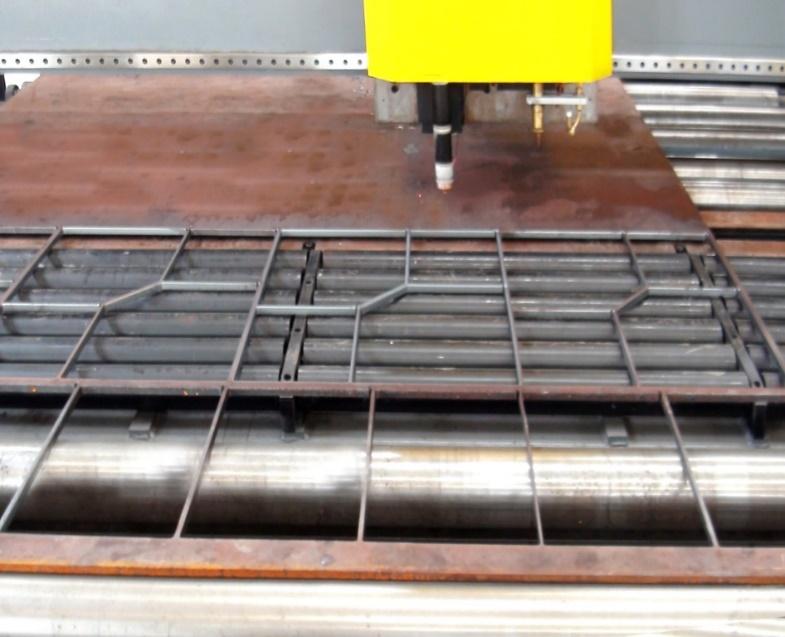

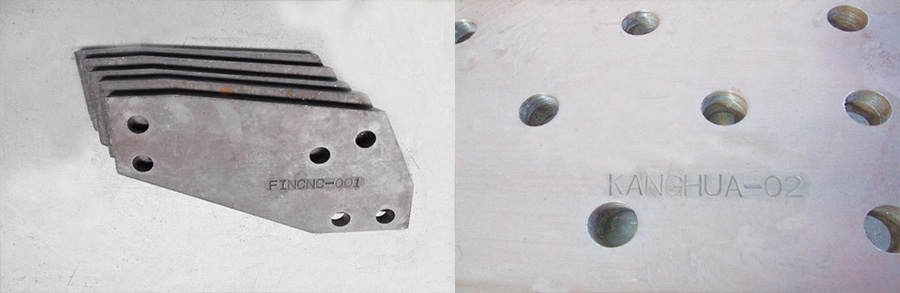

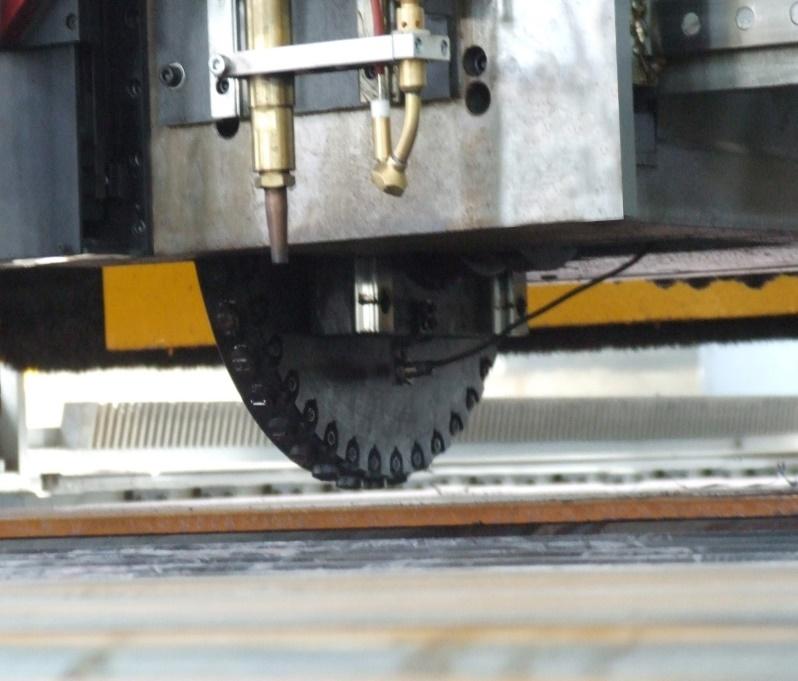

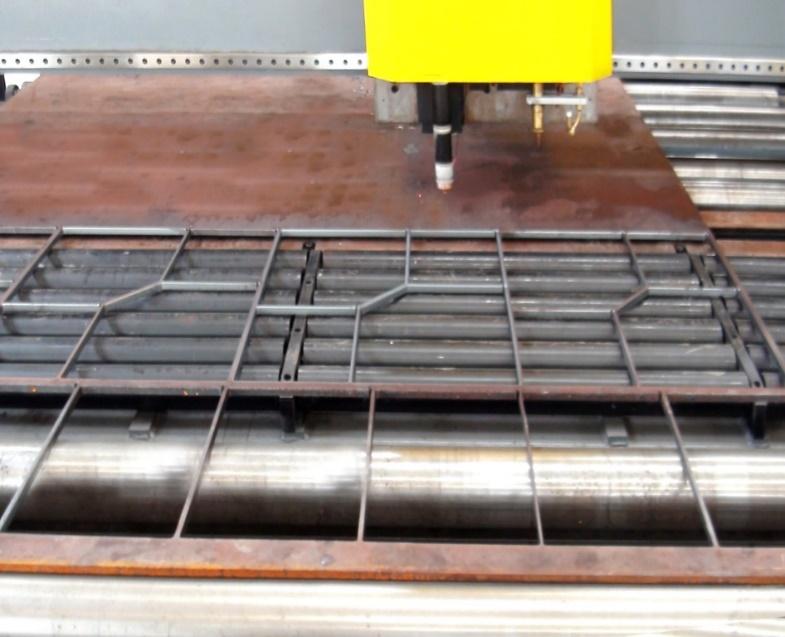

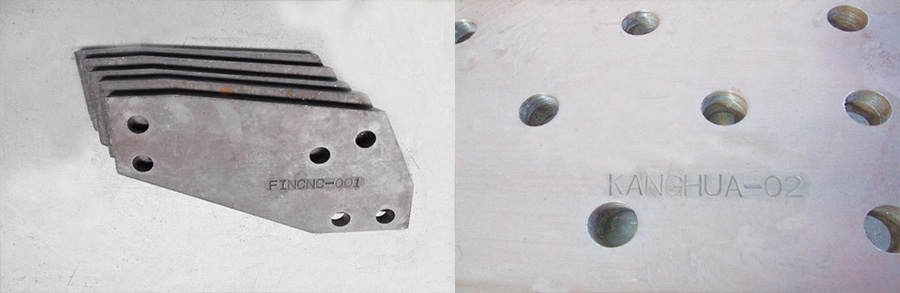

Hydraulic disc for marking with many marking characters, quick character selection and clear marking effect. With plasma and flame cutting ,customer can choose according to their real manufacturing requirement. Dust removing system is mainly used for plasma cutting.It is mainly used to absorb and dispose cutting smother and power to ensure good manufacture environment. It has automatic cutting function (max. cutting workpiece size:3100×500mm). The finished part drops into the finished product box directly.

Processing is :loading-marking-drilling-swarf leaning-cutting-unloading(If the length of waste plate reaches 2500mm,cut of the waste plate).Equipped with imported program software, ease to learn and operate. It can transfer the drawing in electronic version to processing rogram.

It can fulfill nesting function which greatly promotes the material utilization rate.

3、Technical Specifications

Specification name | Items | Specification value |

Workpiece dimension | Max length(mm) | 12000 |

Min length(mm) | 2500 |

Max width(mm) | 3100 |

Min width(mm) | 400 |

Workpiece weight | Max weight(kg) | 7500 |

Plate weight per meter(kg) | ≤750 |

Moving speed | Max. speed of X Y axes(m/min) | 30 |

Drilling spindle headstock | Quantity of drilling unit(piece) | 1 |

Quantity of drilling spindle(piece) | 1 |

Max. drilling diameter(mm) | φ40 |

Max. drilling thickness(mm) | 120 |

Min. drilling thickness(mm) | 10 |

Power of drilling spindle motor(kW) | 18.5 |

Max. rotation of drilling spindle(r/min) | 3000 |

Quantity of tools(piece) | 6 |

Marking unit | Quantity of character(piece) | 38 |

Marking force (kN) | 80 |

Flame cutting | Quantity of torch (piece) | 1 |

Cutting thickness (mm) | 10-130 |

Plasma cutting system (Hyper Hpr260XD) | Cutting thickness(mm) | 10-32 |

Height adjusting system(set) | 1 |

Dust collector system(casic) |

| 1set |

CNC system(optional) |

| 1set |

Automatic programming sofeware(Lantek) |

| 1set |

4.Key outsourced components list:

No. | Name | Brand | Country |

1 | Roller linear guide rail | Hiwin/PMI | China Taiwan |

2 | CNC control system | Siemens/Fagor8055 | Germany/Spain |

3 | Feeding servo motor and servo driver | Siemens/Yaskawa | Germany/Japan |

4 | Precise spindle | Spintech/Kenturn | China Taiwan |

5 | Hydraulic valve | Yuken/Justmark | Japan/China Taiwan |

6 | Oil pump | Justmark | China Taiwan |

7 | Automatic lubricating system | Herg/Bijur | Japan/USA |

8 | Button, Indicator, low voltage electronic components | ABB/Schneider | Germany/France |

9 | Plasma cutting | Hyper | USA |

10 | Height adjusting system | Hyper | USA |

11 | Dust collector system | Kaitian | China |

12 | Drag chain | IGUS | Germany |

13 | Reducer | Atlanda | Germany |

14 | Air cylinder | Airtac | Taiwan China |

Note: The above is our fixed supplier. It’s subject to be replaced by same quality components of other brand if the above supplier can’t supply the components due to any special matter.

5. Work Environment:

1、Power supply: 3 phases 4 lines 380±10%V 50±1HZ

2、Environment temperature:0-40°C

3、Environment humidity: ≤75%

4、Air pressure: ≥0.8MPa