Specification range of H-beam | Maximum flange | 400mm |

|

Maximum Web | 700mm |

|

Length | 3500~12000mm |

|

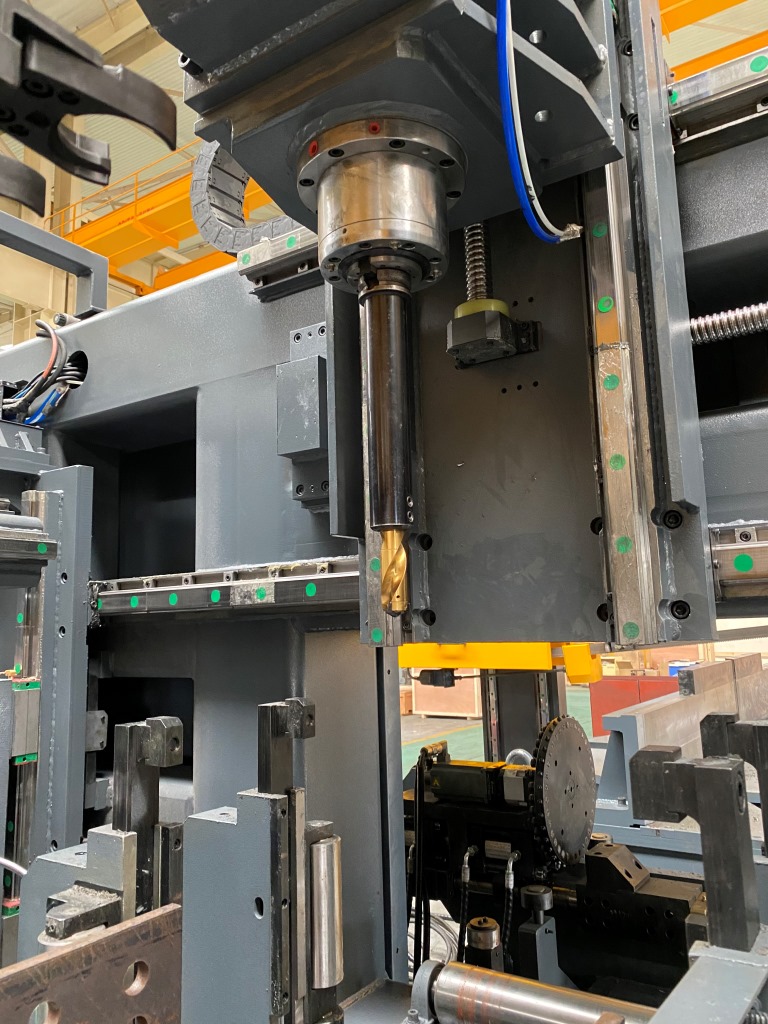

Drilling Machine(BHD700/3) | Processing material | H-beam | Web height | Min.150-Max.700mm

|

Flange width | Min.75- Max.400mm |

U-beam | Web height | Min.150-Max.700mm |

Flange width | Min.75- Max.200 mm |

Max. thickness of material | 60mm |

|

Drilling Spindle | Quantity | 3 |

|

Max. Drilling diameter | Carbide drill ø 30mm Twist drill ø40mm |

|

Spindle taper hole | BT40 |

|

Spindle motor power | 3×11KW |

|

Spindle speed (stepless speed regulation) | 20~2000r/min |

|

Tool magazine | Quantity | 3 |

|

Number of tools | 3×3 |

|

CNC axis | Number of feed axis and positioning axis | 7+3 |

|

Servo motor power of fixed side, moving side and middle side feed shaft | 3×2KW |

|

Fixed side, moving side, middle side, moving side positioning axis servo motor power | 3×1.5KW |

|

Torque of servo motor for feed shaft at fixed side, moving side and middle side | 3×12.5Nm |

|

Fixed side, moving side, middle side, moving side positioning axis servo motor torque | 2×10Nm |

|

Moving speed of three positioning CNC axes | 0~10m/min |

|

Moving speed of three feed CNC axes | 0~5m/min |

|

Width detection stroke | 550mm |

|

Web detection stroke | 190mm |

|

Spray cooling system | Number of nozzles | 7 |

|

Compressed air pressure | 0.8Mpa |

|

Cooling mode | Internal cooling + external cooling |

|

Marking unit(M1250) | Clamp motor power | 0.25KW |

|

Torque of servo motor for font positioning | 2.8 Nm |

|

The power of the servo motor for the word disk positioning | 1KW |

|

Characters numbers | 36 characters (0-9, A-Z) |

|

Positioning speed of marking disk | 35m/min |

|

Clamp positioning speed | 0.223m/min |

|

Table Height | 800 mm |

|

Sawing unit(DJ700) | Sawing H-beam dimensions | At 0 ° Maximum cutting capacity of | 700 *400 mm |

At 45 ° Maximum cutting capacity of | 400 *400mm |

Minimum material size | 150 mm*75 mm |

Cutting Saw blade | T:1.3mm W:41mm |

|

Main motor power | 7.5 kW |

|

Saw blade line speed | 20~100 m/min |

|

Cutting feed rate | 0 ~ 2 m / min program control |

|

Oblique cutting angle | 0°~45° |

|

Table height | About 800 mm |

|

Electrical system | control mode | Upper computer +PLC |

|

Control system | PLC+Bus |

|

CNC axis | 7+3 |

|

Hydraulic system | Motor power | 4Kw+2.2Kw |

|

| system pressure | 6MPa+16MPa |

|

| Hydraulic pump flow | 33L/min+14L/min(1450r/min) |

|

| Tank capacity | 200L+80L |

|